-

Benchmark Simulation Platform

-

Fuel Cell Simulation Platform

-

Thermal Management Simulation Platform

-

Vehicle Dynamics Simulation

-

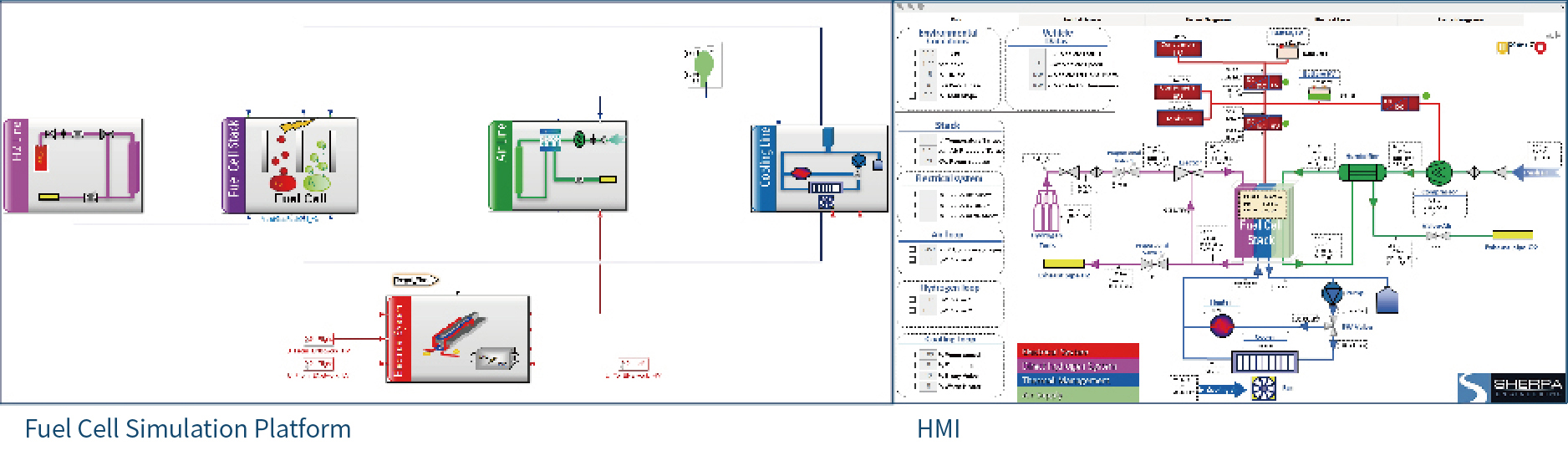

Fuel Cell Simulation Platform

ontrol system design and fuel cell system diagnostics are essential parts. In customer projects, we play a positive role responsible for the system design throughout the entire process from system specifications to demonstrator vehicle validation. vehicle validation.

1.Simulation Platform Introduction

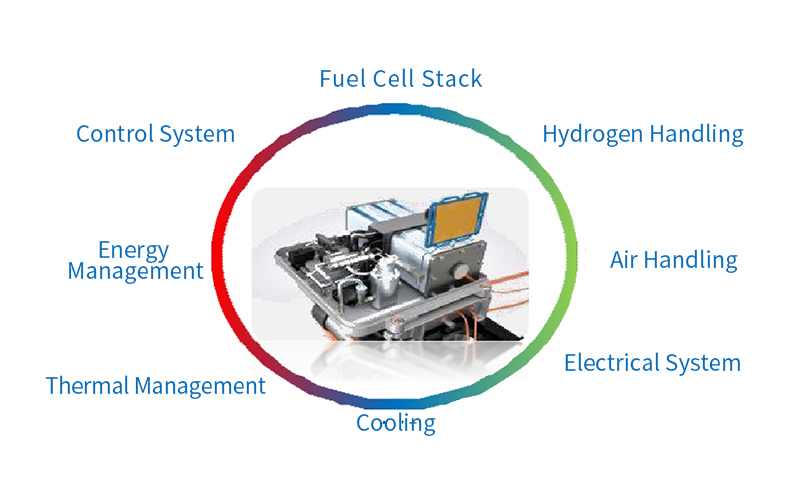

The simulation platform developed by us covers the whole fuel cell system, including its control and powertrain system parts and the following subsystems:

? Air Subsystem: Air is defined by input pressure, flow rate, temperature, and humidity.

? Hydrogen Subsystem: Hydrogen is defined by the input pressure and flow rate.

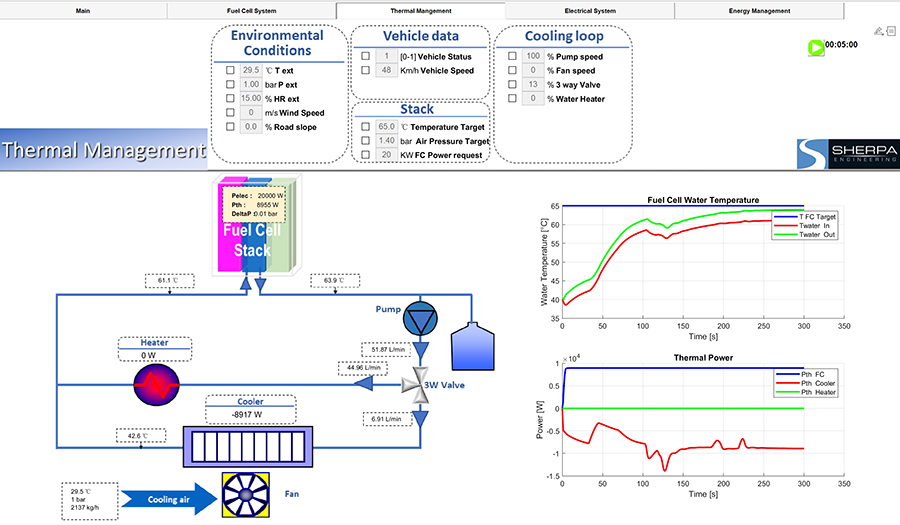

? Cooling subsystem: Ensure sufficient cooling of the fuel cell stack and ensure that the temperature gradient between the stacks is small.

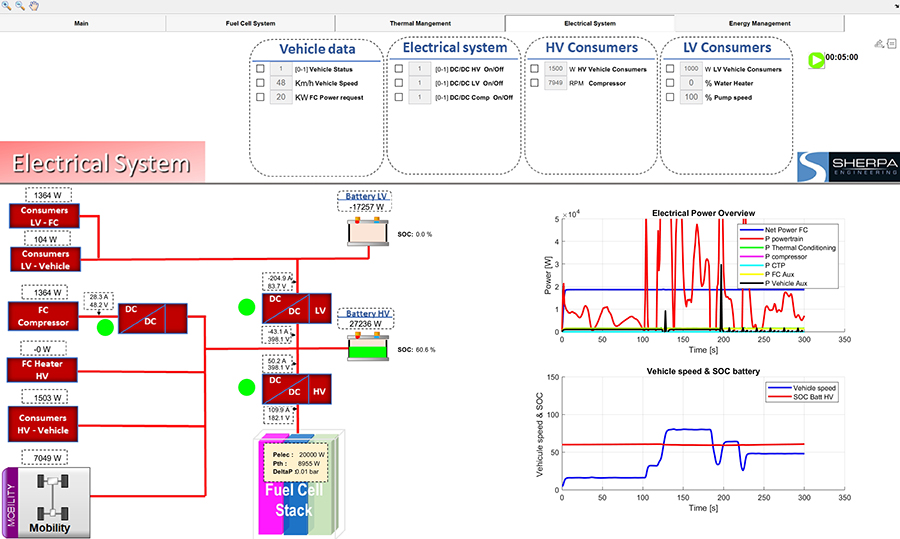

? Electrical Subsystem: Manages the storage and consumption of electrical energy in the various subsystem of the vehicle.

? Powertrain Subsystem: Represent the powertrain of the vehicle.

? Control Subsystem: Basic control principles, diagnosis, monitoring and system regulation.

The electrical subsystem allows you to connect your fuel cell with some of the electrical equipment such as the low voltage, high voltage and drivetrain.

The energy management window, you can adjust the properties of your components and verify the range in different driving scenarios.2.System Design

We have extensive experience in system design and selection of actuators (air compressors, radiators, valves, etc.). We use a dynamic environment model of the system to ensure optimal selection of components (attribute to bond-graph theory). The model is based on the heat flow equation of the system, taking into account the characteristics of each component, thus achieving the requirements of the system.

3.Hydrogen Leak Detection

A common safety issue in fuel cell systems is hydrogen leakage, which can lead to very serious consequences. Therefore, in addition to the hydrogen sensor, we have also developed a leak detection system for fuel cell system. The system includes a hydrogen storage tank, primary shut-off valves, and auxiliary shut-off valves in the supply pipeline.

4.Diagnosis

The purpose of the diagnostic system is to avoid deterioration of the fuel cell stack and to extend its lifetime. We propose a simple and effective diagnosis-oriented model. It includes the following three main monitoring modules:

? Real-time battery voltage monitoring.

? Various parameters for safe and normal operation: Membrane temperature, Air flow, Stoichiometric ratio, Hydrogen and Air pressure stack inlet, Differential pressure,

? Actuator and Sensor Diagnostics.

5.Process Validation

? Hierarchical decomposition: Use partial test benches to validate subsystems before the final validation of the entire fuel cell system.

? Model-based design: Run the same tests on the model, extrapolating its performance in the laboratory or in a real vehicle.

? HIL-compliant: Our model is developed in fixed steps and is consistent with real-time equipment.

Bench Testing

MorePut away

Share

Share